Manual Pipe Threaders

Manual pipe threaders are operated by hand using a ratcheting mechanism, making them a fundamental tool for creating threads on pipes for secure connections .

Advantages of Manual Threaders

- Cost-Effectiveness: Manual threaders are significantly less expensive than their electric counterparts, making them a budget-friendly option for occasional or small-scale projects .

- Portability and Ease of Use: These tools are lightweight and compact, allowing for easy transportation to various job sites, including tight or remote spaces .

- Control and Precision: Manual operation provides a high degree of control, allowing the user to feel the cutting process and make real-time adjustments for a perfect thread .

- No Power Source Required: They do not rely on electricity or batteries, making them ideal for use in locations without a reliable power supply .

Disadvantages of Manual Threaders

- Physical Effort Required: Threading pipes, especially larger ones, can be labor-intensive and time-consuming, requiring significant manual strength and endurance .

- Limited Power: They are less suitable for threading very large pipes or harder materials like stainless steel, which can quickly wear out the dies .

- Lower Efficiency: The process is slower compared to electric threaders, which can be a drawback for high-volume or commercial projects .

Ideal Use Cases

Manual threaders are best suited for:

- Small-scale or occasional projects like hot-water tank installations or gas furnace replacements .

- Jobs in confined spaces where a bulky electric machine would be impractical .

- Budget-conscious operations where the initial investment is a primary concern .

Electric Pipe Threaders

Electric pipe threaders are powered machines that automate the threading process, significantly reducing the physical effort required and increasing efficiency . They are available in various forms, including portable handheld units and stationary shop models .

Advantages of Electric Threaders

- Increased Productivity: Electric threaders can handle a wider range of pipe sizes and materials, making them ideal for high-volume, industrial, or commercial projects .

- Reduced Operator Fatigue: By automating the threading process, these machines significantly reduce the physical strain on the operator, allowing for longer work periods without tiring .

- Uniformity and Accuracy: Electric threaders can produce more consistent and accurate threads, especially for larger pipes, which is crucial for preventing leaks and ensuring secure connections .

- Versatility: Many models are versatile and can perform multiple tasks such as cutting, grooving, and beveling by simply changing the dies .

Disadvantages of Electric Threaders

- Higher Initial Cost: The purchase price of an electric threader is significantly higher than that of a manual one, often ranging from $2,000 to $5,000 or more for professional-grade models .

- Less Portability: Stationary electric threaders are heavy and not easily transportable, while even portable models require access to a power source, limiting their use in remote locations .

- Maintenance and Complexity: They are more complex machines with more parts, which can require more technical knowledge for maintenance and repairs .

Ideal Use Cases

Electric threaders are the preferred choice for:

- Contractors and maintenance technicians who perform threading tasks frequently throughout the year .

- Projects involving large-diameter pipes or materials that are difficult to thread manually, such as thick-walled metal pipes .

- Workshop or shop environments where the machine can be set up permanently for high-volume production .

Key Factors to Consider When Choosing

When deciding between a manual and electric pipe threader, consider the following key factors:

| Feature | Manual Pipe Threader | Electric Pipe Threader |

|---|---|---|

| Initial Cost | Low | High |

| Power Source | None required | Electricity required |

| Portability | Very high | Low to moderate |

| Operator Effort | High (manual labor) | Low (automated) |

| Threading Speed | Slow | Fast |

| Thread Consistency | Good, but depends on operator | High and consistent |

| Suitability for Large Pipes | Limited | Excellent |

| Maintenance Complexity | Low | Moderate to high |

| Ideal for | Small projects, occasional use, tight spaces | High-volume work, large pipes, professional use |

Scenarios for Choosing Each Type

Choose a Manual Threader If:

- Your projects are small-scale or infrequent, such as a few threads for a hot-water tank replacement .

- You work in tight or remote locations without access to electricity .

- Budget is a primary concern, and you do not need the speed or power of an electric model .

Choose an Electric Threader If:

- You perform threading tasks regularly, as the initial investment can be justified by long-term savings and efficiency .

- You work with large-diameter pipes or materials that are difficult to thread manually, such as stainless steel .

- Your job requires high productivity, consistent thread quality, and reduced physical strain on the operator .

Additional Considerations

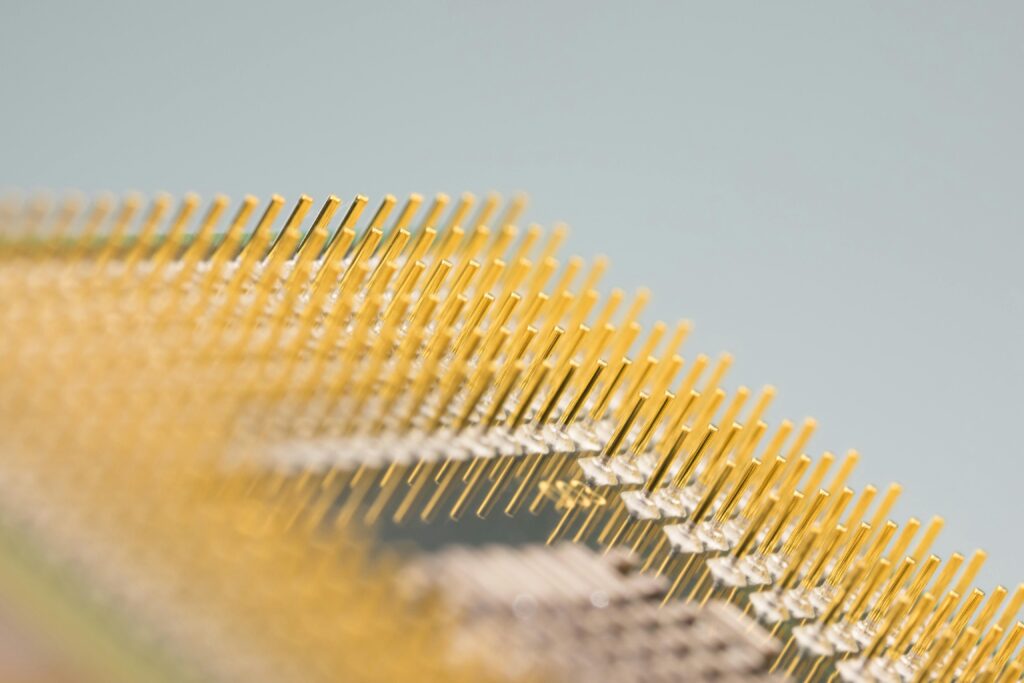

- Die Quality: The quality of the threading dies is crucial for producing clean, sharp, and uniform threads. Look for dies made from durable materials like high-speed steel or alloy .

- Warranty and Support: Consider the warranty period and availability of after-sales support and spare parts, which are essential for maintaining performance and longevity .

- Rental vs. Purchase: For contractors with occasional threading needs, renting a professional-grade electric threader can be a cost-effective solution, providing access to high-quality equipment without the long-term commitment of ownership .

Please login to write a comment after