Essential Maintenance Practices for Pipe Cutting Tools

Maintaining pipe cutting tools is critical for ensuring precision, safety, and longevity. A proactive approach to maintenance can prevent costly breakdowns and ensure consistent performance .

Daily and Routine Cleaning

Regular cleaning is the first line of defense against tool wear and performance issues.

- Post-Use Cleaning: After each use, remove metal chips, dust, and oil stains from the machine's body, guide rails, clamps, and cutting area. Use an air gun or brush to clean the blade area to prevent buildup that affects cutting precision .

- Deep Cleaning: For power tools, a daily cleaning regimen should include using compressed air to blow out dust and debris from motor vents, chuck mechanisms, and gear housings. If used in wet environments, ensure the tool is completely dry before storage to prevent corrosion .

- Cleaning Plastic Cutters: For plastic pipe cutters, wipe down the cutting wheel and moving parts with a clean cloth after each use. For stubborn debris, use a damp cloth with mild soap, then dry the tool completely to prevent rust .

Lubrication of Moving Parts

Proper lubrication minimizes friction, prevents wear, and ensures smooth operation of moving components.

- Application: Apply lubricant to guide rails, lead screws, transmission chains, and pivot points. Use the lubricant recommended by the manufacturer to avoid damaging seals or valves .

- Frequency: Lubrication should be performed at least once a week for frequently used machines. Pneumatic tools may require daily oiling through air line lubricators, while electric drills may need lubrication monthly .

- Lubricant Type: Use a light oil or silicone-based lubricant for plastic cutters. Avoid heavy greases as they can attract dust and debris. Never use automotive oils in pneumatic tools, as they can damage internal components .

Inspection and Component Replacement

Regular inspections help identify wear and potential failures before they impact performance.

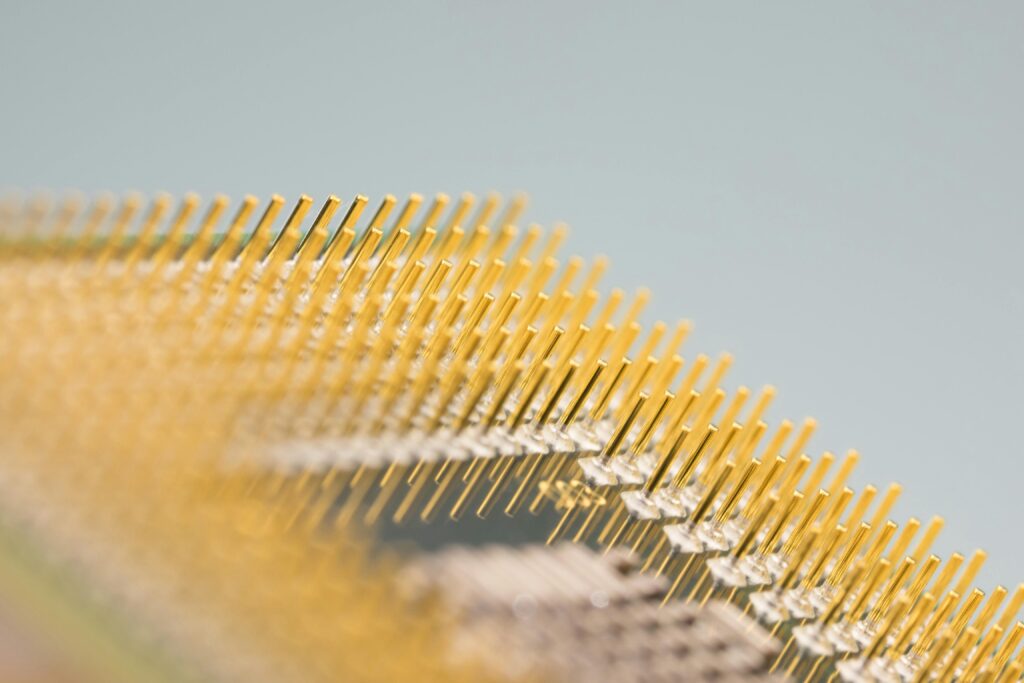

- Cutting Components: Check saw blades, cutting wheels, and other cutting tools for wear, dullness, or damage. Replace blades or wheels that are nicked, cracked, or otherwise compromised .

- General Inspection: Inspect all parts of the tool for signs of damage, such as cracks, rust, or loose components. Pay special attention to the locking mechanism, handles, and any fasteners holding the cutting blade in place .

- Electrical Systems: For electric tools, inspect wiring for aging, looseness, or short circuits. Check the condition of power cords, plugs, and internal components to ensure stable operation and prevent electrical hazards .

Safety and Operational Checks

Prioritizing safety is essential to prevent accidents and ensure the tool functions as intended.

- Daily Safety Checks: Before each use, inspect the machine's electrical systems, emergency stops, and safety guards to ensure they are in proper working order .

- Secure the Pipe: Always secure the pipe firmly in place before cutting to prevent it from shifting, which can lead to inaccurate cuts or accidents .

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety goggles, heavy-duty gloves, and steel-toe boots, to protect against flying debris, sharp edges, and falling objects .

- Correct Tool Use: Use the right tool for the job and the specific material. For example, use a cutting wheel suitable for the type of pipe being cut (e.g., thin wheel for steel, stout wheel for cast iron) .

Preventive Maintenance and Storage

A structured maintenance schedule and proper storage extend the tool's lifespan.

- Preventive Maintenance Schedule: Establish a preventive maintenance plan with specific intervals for tasks like internal cleaning, calibration checks, and professional servicing .

- Proper Storage: Store tools in a dry, climate-controlled environment to prevent rust and corrosion. For cutting tools, store them in protective cases or racks to prevent accidental damage. Ensure blades are covered or detached when not in use .

- Documentation: Maintain a service log for each tool, recording purchase dates, service history, and any performance issues. This data helps predict failures and optimize replacement schedules .

Common Mistakes to Avoid

Avoiding common errors is crucial for maintaining tool performance and safety.

- Over-Crimping/Over-Cutting: Applying excessive force can deform the pipe or damage the fitting. Always follow manufacturer guidelines for crimping pressure .

- Using the Wrong Tool: Using a tool not designed for the pipe material or size can lead to poor cuts and potential damage to the tool or workpiece .

- Neglecting Training: Proper training ensures operators know how to select the correct tool, apply consistent pressure, and inspect finished connections .

Summary Table of Best Practices

The table below summarizes key maintenance practices for different types of pipe cutting tools.

| Maintenance Task | Description | Recommended Frequency | Key Source(s) |

|---|---|---|---|

| Cleaning | Remove chips, dust, and debris from all parts. Use compressed air or brushes. | After each use | |

| Lubrication | Apply recommended lubricant to moving parts like rails, bearings, and pivot points. | Weekly (daily for pneumatic tools) | |

| Component Inspection | Check cutting blades, wheels, and other components for wear, dullness, or damage. | Daily/Weekly | |

| Electrical Inspection | Check wiring, cords, and internal components for damage or wear. | Monthly | |

| Safety Checks | Inspect emergency stops, guards, and secure the pipe before cutting. | Daily | |

| Proper Storage | Store tools in a dry, protected area. Cover or detach blades when not in use. | After each use | |

| Preventive Maintenance | Schedule deeper service, calibration, and internal cleaning. | Quarterly/Annually |

Please login to write a comment after