Key Factors Influencing Corrosion Resistance

The corrosion resistance of construction nails is determined by a combination of material composition, protective coatings, and environmental conditions. Selecting the right nail for a specific application involves understanding how these factors interact to affect durability and longevity.

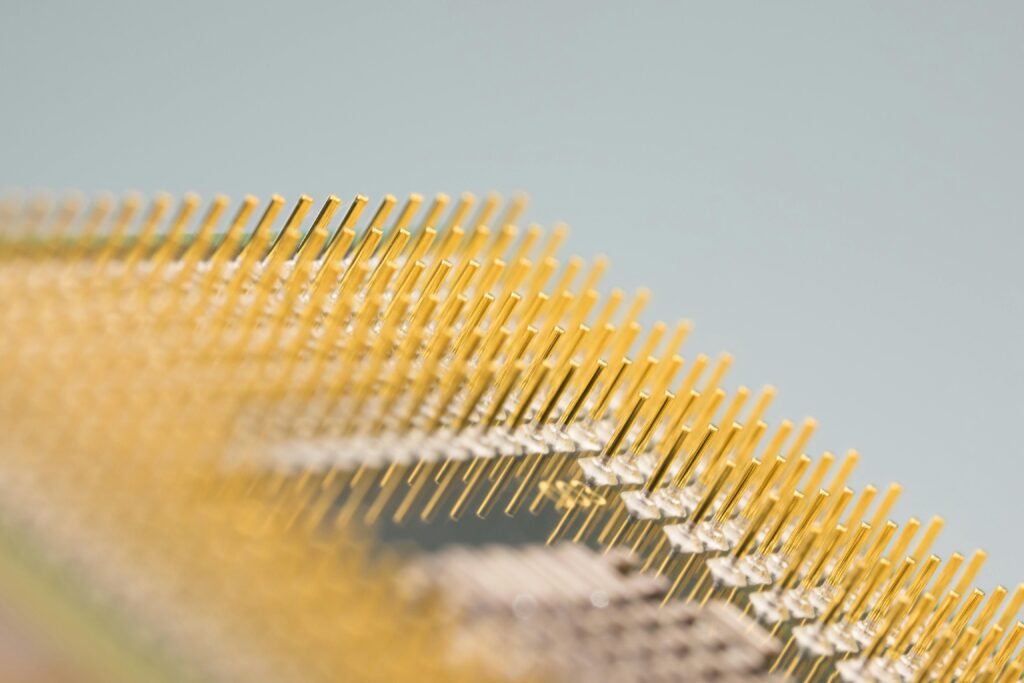

Nail Material Composition

The base material of a nail is the primary determinant of its inherent resistance to corrosion. Different metals offer varying levels of protection against rust and chemical degradation.

- Steel: The most common material for construction nails due to its strength and cost-effectiveness. However, plain steel is highly susceptible to rust when exposed to moisture and oxygen. To improve its durability, steel nails are often coated with other metals .

- Stainless Steel: An alloy of steel that includes chromium, which forms a passive layer of chromium oxide on the surface. This layer prevents further oxidation and provides excellent corrosion resistance, making stainless steel ideal for exterior applications and harsh environments like coastal areas . It is more expensive than other materials but offers superior longevity .

- Aluminum: A lightweight metal with good natural corrosion resistance. It is less strong than steel and is typically used for softer woods or applications where weight is a concern, such as in lightweight structures or for aesthetic purposes .

- Copper: Known for its excellent corrosion resistance and aesthetic appeal, copper is primarily used for specialized applications where visual appeal is important, such as decorative trim. However, its high cost limits its use in general construction .

Protective Coatings

To enhance the corrosion resistance of less expensive materials like steel, various protective coatings are applied. These coatings act as barriers between the metal and the environment, preventing moisture and chemicals from causing rust.

| Coating Type | Description | Corrosion Protection | Common Applications |

|---|---|---|---|

| Galvanized | A zinc coating applied via hot-dip or electroplating. Hot-dip galvanizing creates a thick, metallurgically bonded layer that provides both barrier and sacrificial protection. Electroplating results in a thinner, shiny layer that is more cosmetic than protective . | High (Hot-dip), Moderate (Electroplated) | Outdoor structures, pressure-treated wood, general construction |

| Electroplated | A thin layer of zinc or another metal deposited using an electric current. This coating is primarily used for its bright, shiny appearance and offers limited corrosion protection compared to hot-dip galvanizing . | Low to Moderate | Indoor applications, where appearance is a priority |

| Phosphate | A thin, rough layer of zinc phosphate applied to the nail's surface. This coating is not designed for high corrosion resistance but is used to increase pull-out resistance, helping the nail hold more securely in the wood . | Low | Applications where holding power is more critical than corrosion resistance |

| Polymer/Epoxy | A plastic coating that provides a durable barrier against moisture and chemicals. These coatings can be colored for aesthetic purposes and offer good protection, though they can be damaged during installation . | High | Decorative applications, humid environments |

| Paint | A layer of paint applied for aesthetic reasons. It can provide some barrier protection against moisture but is generally less durable than other coatings and can chip or wear off over time . | Low | Decorative trim, interior applications |

Environmental Conditions

The environment in which the nails are used is a critical factor in their longevity. Moisture, temperature, and exposure to chemicals all accelerate the corrosion process.

- Moisture: Water is the primary catalyst for rust. Nails used in outdoor applications, bathrooms, or other high-moisture environments require superior corrosion resistance. Moisture accumulation in wood can lead to corrosion of embedded metal fasteners, which can compromise the structural integrity of the building .

- Saltwater and Coastal Environments: Saltwater is highly corrosive. Building codes in coastal regions often mandate the use of stainless steel fasteners, as standard galvanized nails are insufficient to withstand the aggressive environment .

- Wood Type and Treatment: The type of wood and any chemical treatments it undergoes can also affect nail corrosion. For example, pressure-treated wood (like CCA or ACQ-treated wood) contains chemicals that can accelerate the corrosion of certain metals. Building codes typically require hot-dip galvanized nails for use with pressure-treated wood, as they are the only carbon steel fasteners recognized as suitable for this application .

Industry Standards and Specifications

To ensure consistent quality and performance, the construction industry has established standards for nail materials and coatings. Adherence to these standards is crucial for meeting building codes and ensuring long-term durability.

- ASTM International: Publishes numerous standards that specify the dimensions, material properties, and performance requirements for nails. For example, ASTM A153 defines the requirements for hot-dip galvanized nails, with Class D being a common standard for construction applications .

- Building Codes: Local building codes, such as the California Standard for Residential Construction, provide specific requirements for fasteners in different environments. These codes often dictate the minimum level of corrosion resistance required based on the building's location and exposure to the elements. For instance, fasteners in coastal areas may be required to be made of stainless steel, while those in less aggressive environments may only need to be galvanized .

Conclusion

The corrosion resistance of construction nails is a multifaceted issue influenced by the material's inherent properties, the protective coatings applied, and the specific environmental conditions of the application. By carefully selecting the appropriate nail type and coating based on these factors, builders can ensure the structural integrity and longevity of their projects.

Please login to write a comment after