Essential Maintenance Practices for Pipe Cutting Tools Maintaining pipe cutting tools is critical for ensuring precision, safety, and longevity. A proactive approach to maintenance can prevent costly breakdowns and ensure consistent performance . Daily and Routine Cleaning Regular cleaning is the first line of defense against tool wear and performance issues. Post-Use Cleaning: After each […]

Author Archives: beixiaoyi

General Best Practices for All Pipe Cutting Tools Regardless of the tool type, certain maintenance practices are universally important for ensuring longevity and performance. Daily Cleaning: After each use, remove debris, chips, and dust from the tool’s body, guide rails, clamps, and cutting area. This prevents buildup that can affect precision and function . For […]

The Role of Cutting Oil in Pipe Threading Cutting oil, or thread cutting oil, is a specialized lubricant designed to reduce friction and heat during the metalworking process of threading . Its primary functions are to lubricate the cutting tool, cool the workpiece and tool, protect against wear, and improve the quality of the final […]

Key Functions of Cutting Oil Cutting oil serves several critical functions during the threading process. A high-quality cutting oil is specifically formulated to perform these tasks effectively, while a poor-quality or inappropriate oil can lead to significant issues . Lubrication and Friction Reduction: The primary role of cutting oil is to lubricate the interface between […]

Key Factors Affecting Pipe Cutter Durability The durability of a pipe cutter is influenced by a combination of factors, including the tool’s construction, the materials it is used on, and the user’s maintenance practices. Understanding these factors can help extend the lifespan of the tool and ensure consistent performance. Tool Construction and Quality The physical […]

Manual Pipe Threaders Manual pipe threaders are operated by hand using a ratcheting mechanism, making them a fundamental tool for creating threads on pipes for secure connections . Advantages of Manual Threaders Cost-Effectiveness: Manual threaders are significantly less expensive than their electric counterparts, making them a budget-friendly option for occasional or small-scale projects . Portability […]

Key Factors in Material Selection The choice of material for high-temperature slurry pump components depends on several critical factors : Fluid Compatibility: Understanding the chemical properties of the slurry is the first step. The material must be compatible with the fluid to prevent rapid degradation . Corrosion Resistance: For slurries containing acids, alkalis, or other […]

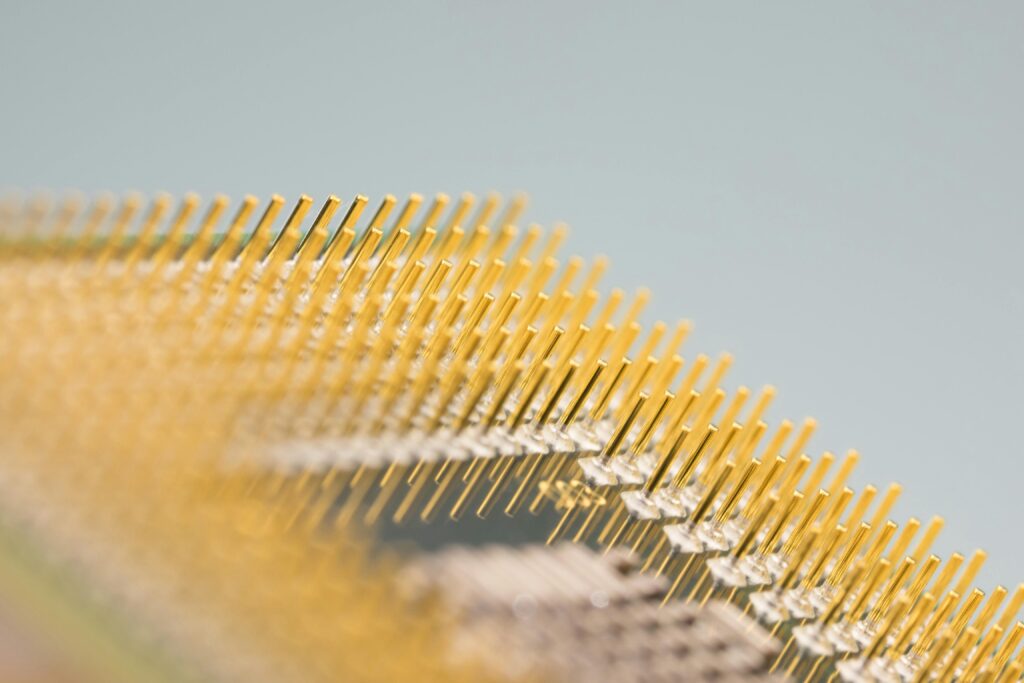

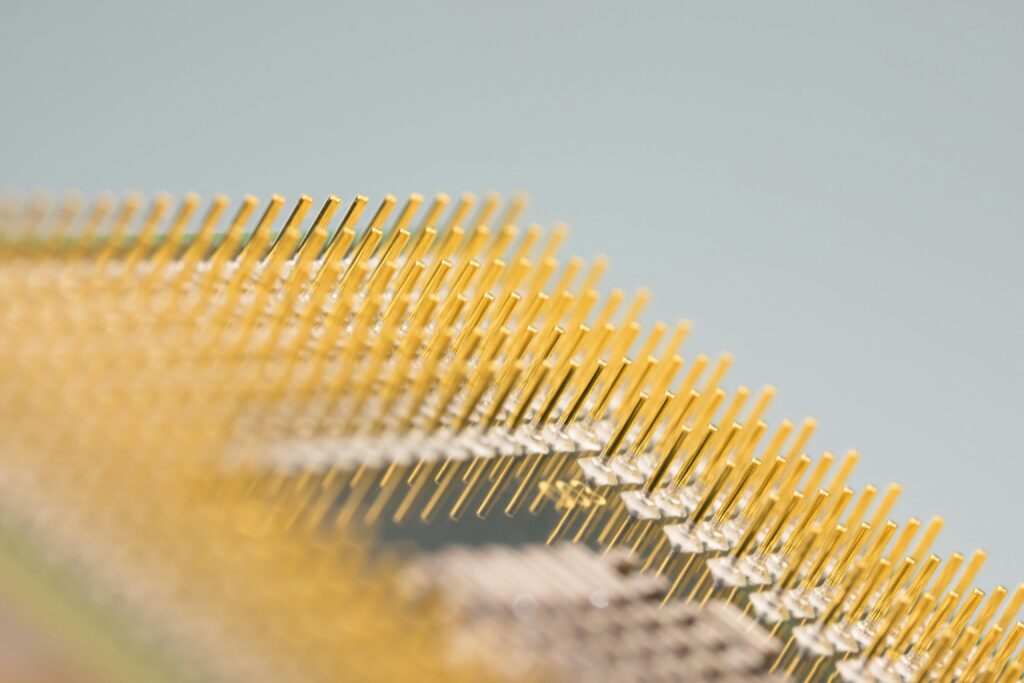

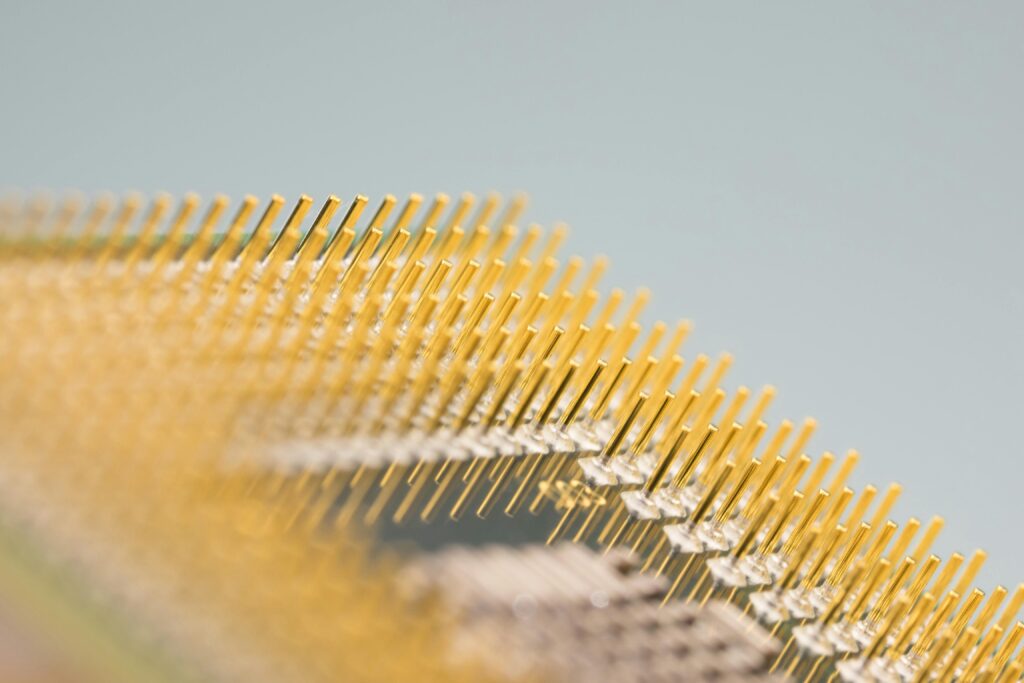

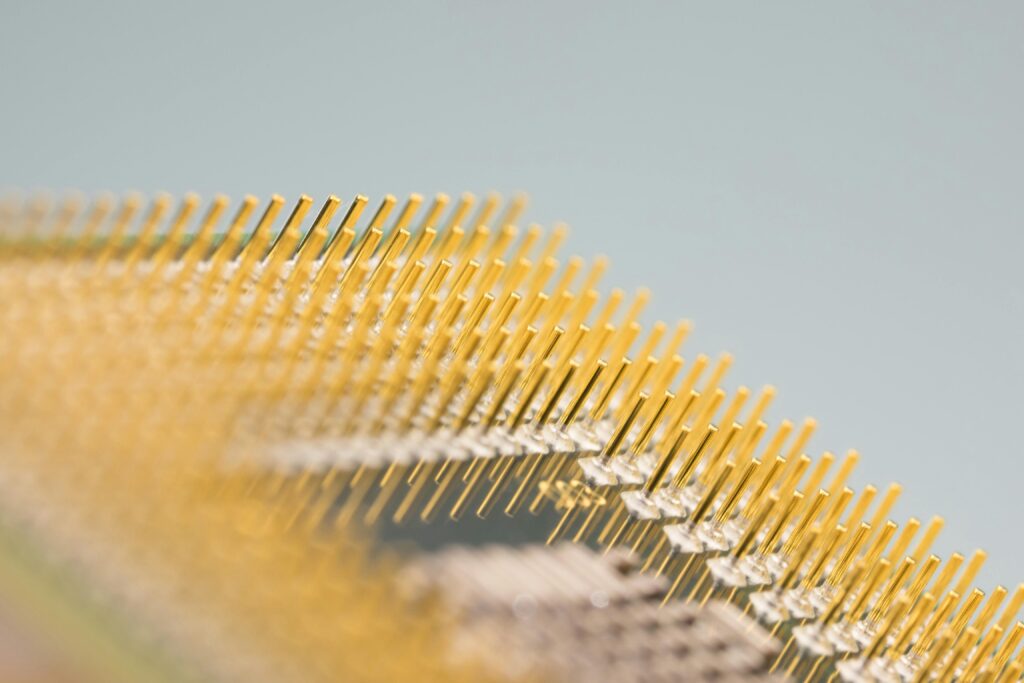

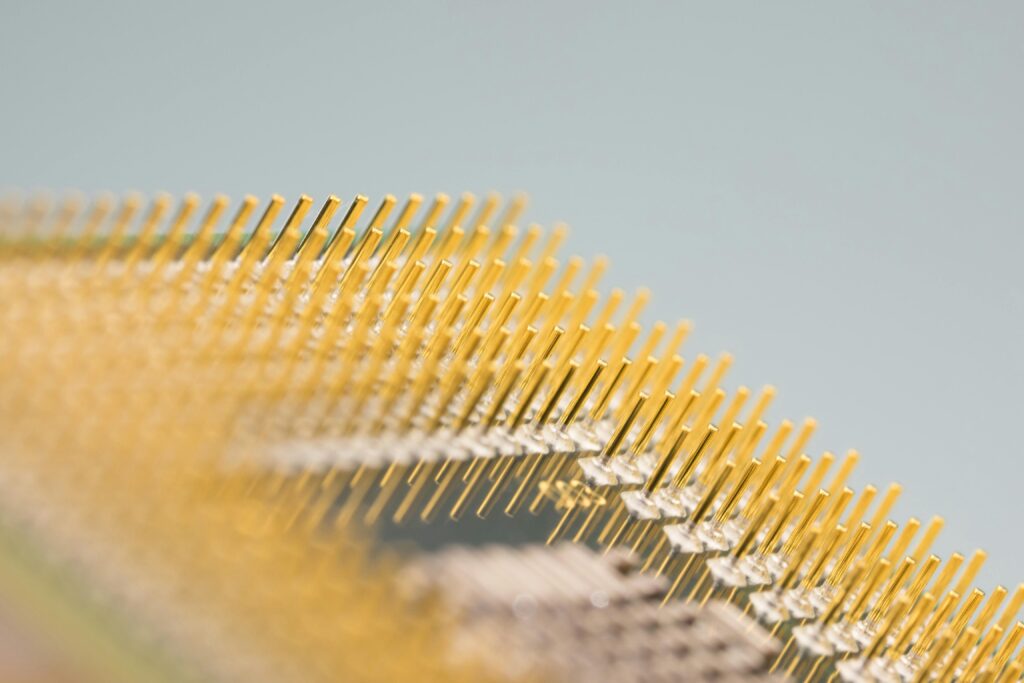

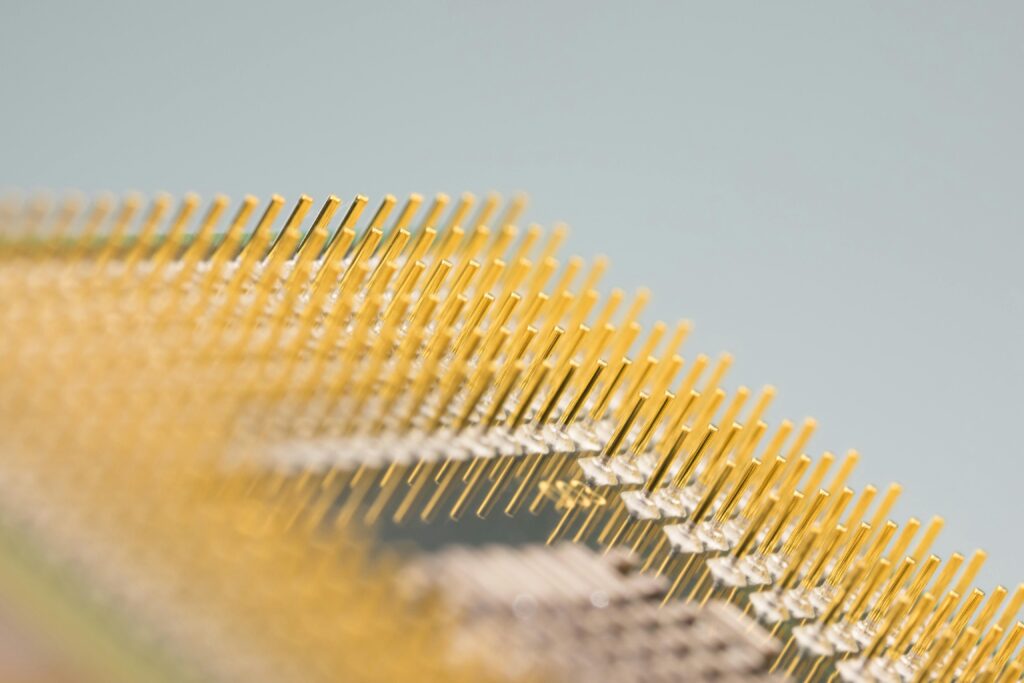

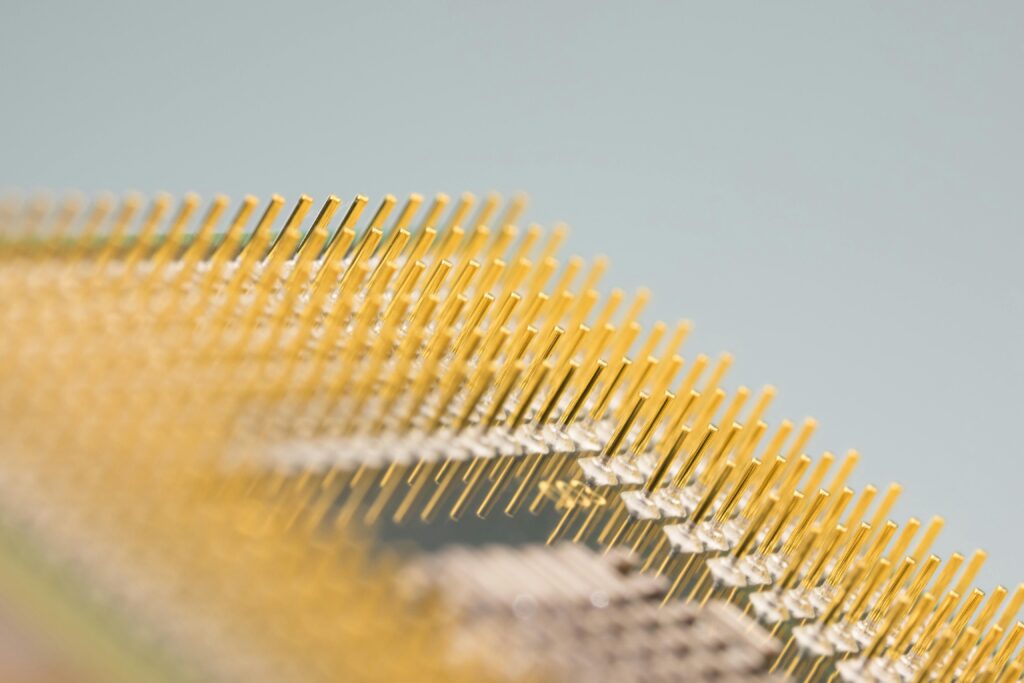

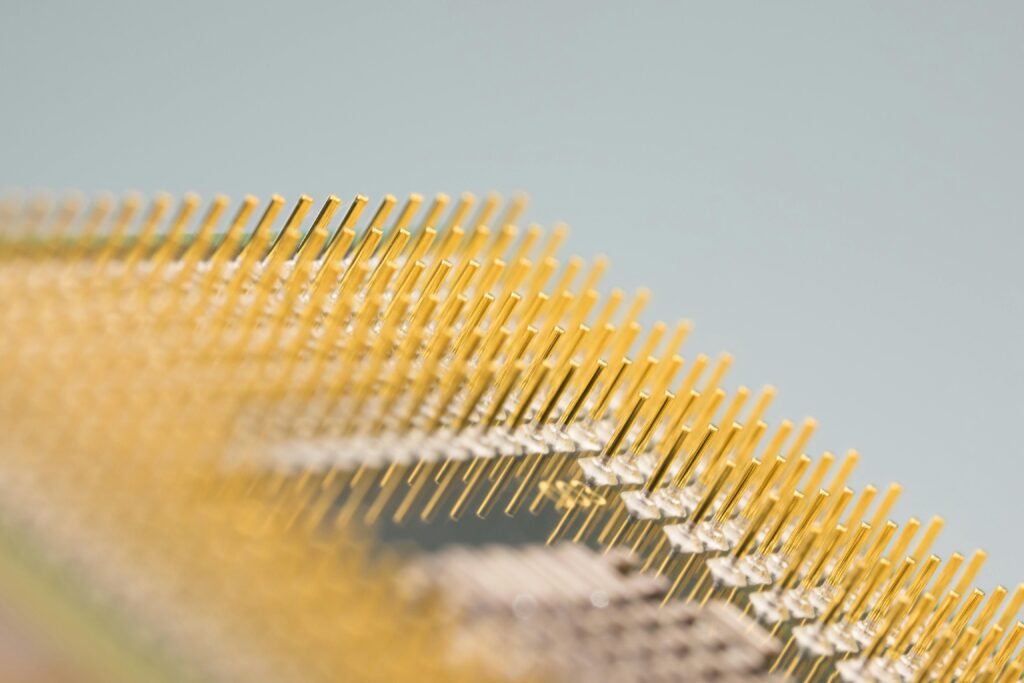

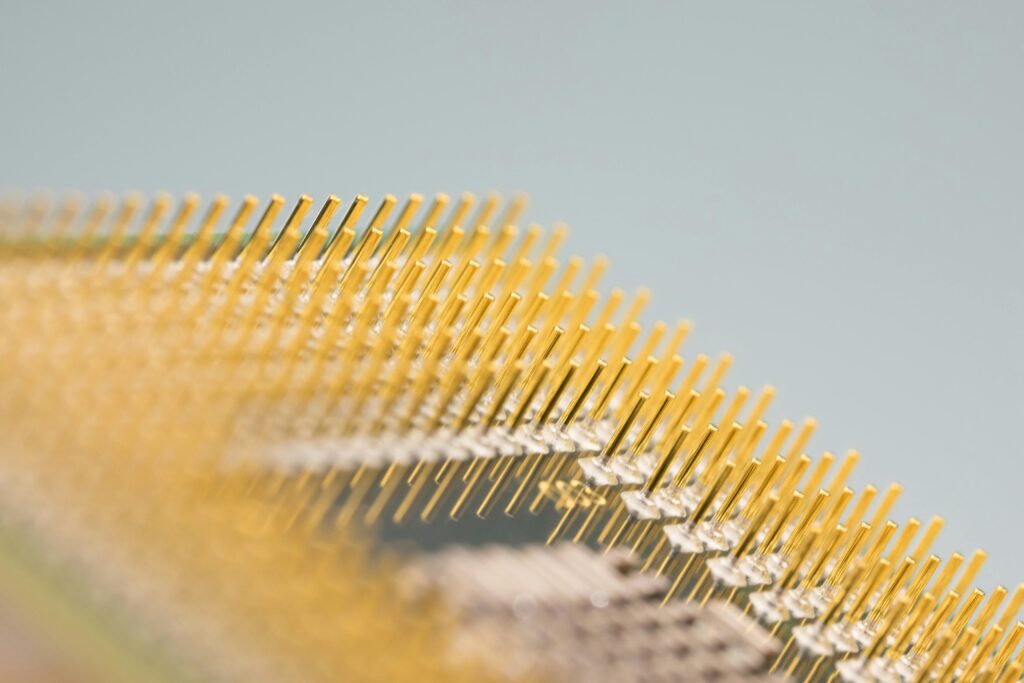

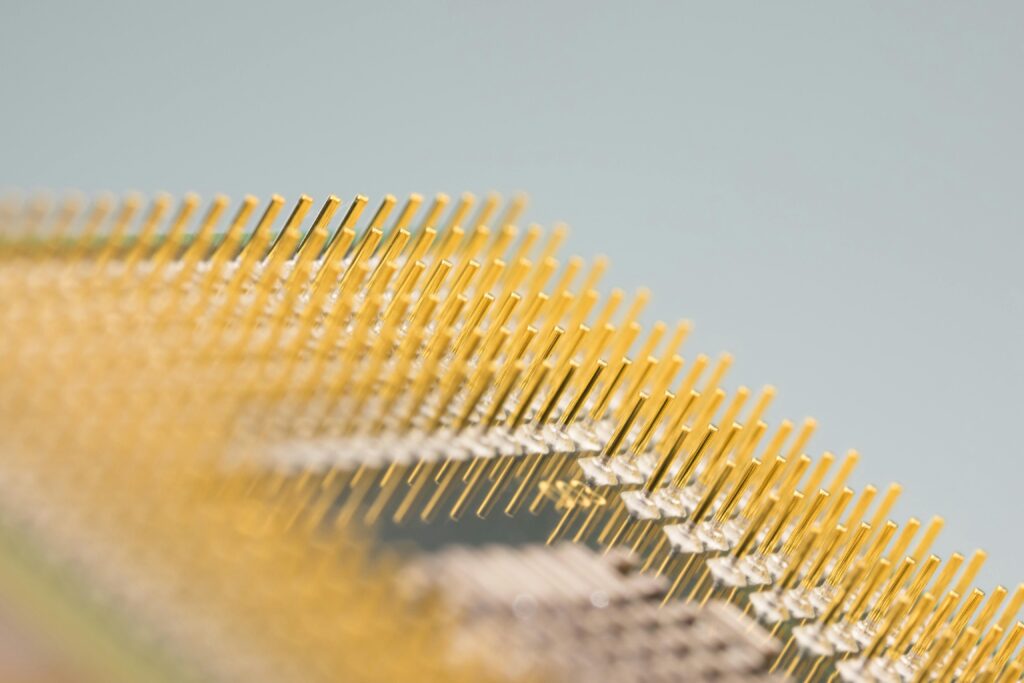

Key Factors Influencing Corrosion Resistance The corrosion resistance of construction nails is determined by a combination of material composition, protective coatings, and environmental conditions. Selecting the right nail for a specific application involves understanding how these factors interact to affect durability and longevity. Nail Material Composition The base material of a nail is the primary […]

Key Factors in Material Selection Choosing the right material for a high-temperature slurry pump is critical to its performance and longevity. The decision should be based on several key factors: Slurry Characteristics: The nature of the slurry is the primary consideration. This includes its abrasiveness, corrosiveness, chemical composition, particle size, and concentration . For example, […]

Temperature and Slurry Viscosity Temperature is a primary factor that influences the viscosity of a slurry, which is a mixture of solid particles suspended in a liquid. The viscosity of a fluid determines its resistance to flow, directly impacting the power required to pump it . High Temperatures: As temperature increases, the viscosity of most […]